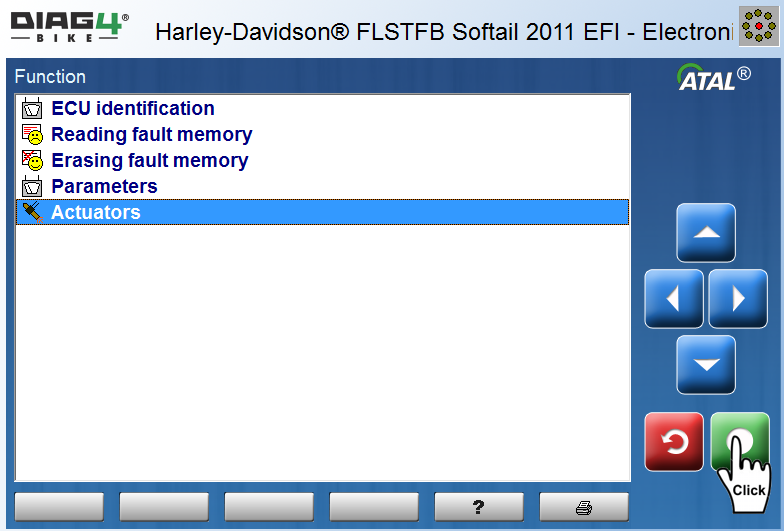

3.5. Actuators

The control unit controls and influences the engine run and other relating components by means of actuating units. Certain elements can be controlled with an assistance of the control unit without the need for a disassembly. The advantage also lies in the fact you test the element with the inclusion of cabling and connector couplings on the vehicle. The range of elements which can be tested in this way is determined by the capacity of the control unit of the applied system and, of course, by the vehicle outfit as well.

In principle, the very test is performed in the following way: the control unit gives the tested actuating unit the commands to act and, simultaneously, the element activity is monitored. Then the result can be measured and displayed back directly by the control unit or in the co-operation with a mechanic – S/he detects the actual element activity either by means of his/her senses (audible clapping when valves are opened or relays switched, the jetting of fuel when the injection valve is switched, and the like) or with the use of measuring instruments. When the function of the actuating unit is correct, we are sure the element and cabling are correct as well. Failing which, a search for the cause of failure must continue.

Most of the tests must be performed with a stopped engine, some with an engine either stopped or running, and with some the engine in run is necessary. The vehicle should be at a standstill and secured against spontaneous movement. The device reacts to the control system responses and, if necessary, it draws operator’s attention to the necessity of a pertinent intervention. Generally, the duration of the test is finite – in some cases the test ends in reaction to the control unit response, in other cases it can be interrupted either by pressing a return key or it is ended automatically after a certain period (within approximately 30 s – it depends on a specific test and system).

If, by any reason, the communication between the device and the vehicle control unit was interrupted during actuating units testing, we recommend to switch off the ignition key and continue only after several seconds. By doing so you will avoid possible problems when the control unit finds itself in an incorrect state or in a state different from that presupposed by the diagnostic instrument.

The offered functions may differ depending on the type of control unit |

| List of active diagnostics functions for version Diag4Bike 20.3 |

| ECM |

| IAC Stepper |

| Active Exhaust Control |

| Air Cleaner Intake Valve |

| Cooling pump/Cooling Relay |

| Chassis Fan |

| Fan A |

| Fan B |

| Throttle Actuator Sweep |

| Purge Solenoid Duty Cycle |

| Idle speed control |

| BCM |

| Left Turn Signal |

| Right Turn Signal |

| Brake Lamp |

| Fuel Pump |

| ABS |

| Front apply solenoid |

| Front apply solenoid Left/Right |

| Front Release solenoid |

| Front Release solenoid Left/Right |

| Rear apply solenoid |

| Rear apply solenoid Left/Right |

| Rear Release solenoid |

| Rear Release solenoid Left/Right |

| Pump Motor Voltage Front /Rear |

| Pump motor voltage |

| Speedometer |

| Speedometer |

| Battery lamp |

| Low fuel |

| Check engine lamp |

| Six gear lamp |

| Speed pointer LED |

| LCD |

| Left turn Telltale |

| Right turn Telltale |

| Neutral indicator Lamp |

| High beam indicator lamp |

| Oil telltale |

| ABS lamp |

| Security telltale |

| Cool lamp |

| Cruise Enable |

| Cruise set |

| Tachometer |

| Traction Control Telltale Serengeti |